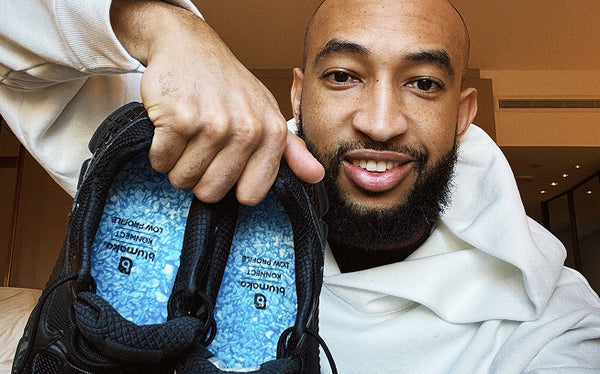

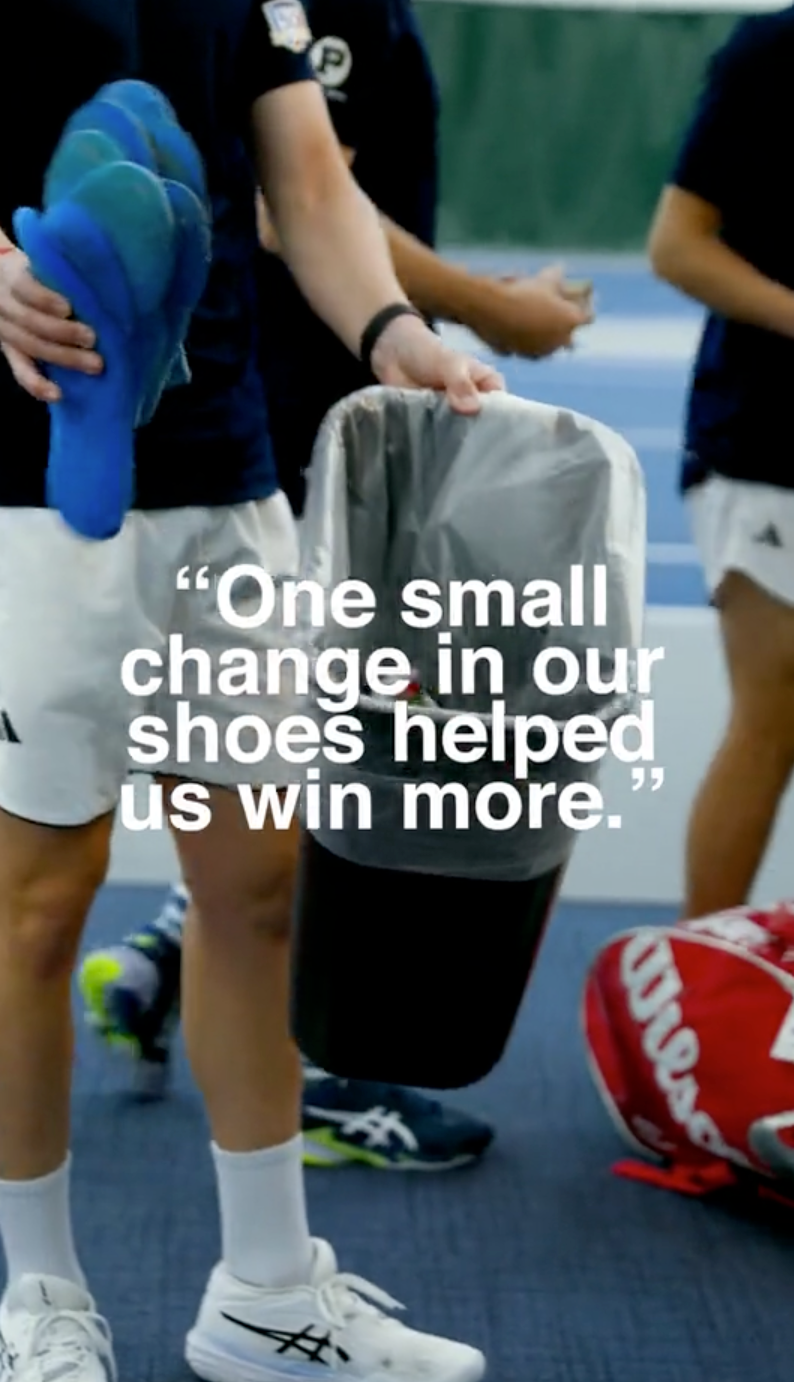

Lab Tested, Athlete Proven: Professional Athlete Study Confirms ‘FoamLock’ Delivers Unrivalled Performance Improvements…

In testing held at a professional sports team’s biomechanical lab, 200 athletes put our ‘FoamLock’ technology through its paces. Scientifically valid results proved that our NonSlip performance insoles helped…