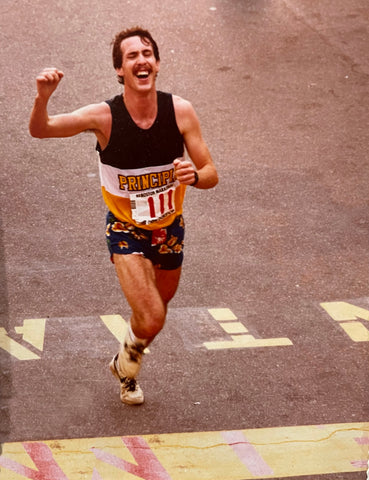

Stuart Jenkins, Boston Marathon, 1983

Hello and Welcome

After more than 45 years immersed in the footwear industry and a journey spanning the globe, I've clocked enough miles to encircle the Earth and then some. From my roots as a youngster in rural Nebraska to competing in Olympic Trials and World Majors, I've worn out countless pairs of shoes – even resorting to modifying pancake-flat Adidas trainers with a butcher knife in my childhood kitchen for enhanced performance.

My mother, the venerable Frances Jenkins, wasn’t thrilled with me using her knife. She didn’t tolerate complaining. Whether I was a kid grousing about the limited flexibility of my shoes, or a seasoned footwear pro reeling from the vast amount of waste I witnessed piling up, she demanded action.

Her response? “Do Better.”

Her spirit has played a pivotal role in fueling my determination to tackle challenges head-on. Throughout my career in footwear development while collaborating with major brands, I've been fortunate to connect with individuals eager for change and steadfast enough to see it through.

Looking at the footwear industry’s foam waste problem, I helped create Blumaka to turn the mounting foam waste into performance footwear.

At Blumaka, we're redefining athletic performance and pioneering a new era of eco-consciousness in the industry. Our flagship performance product, our insoles, incorporate up to 85% recycled content and are made using cleaner manufacturing–near-zero water and no chemicals. Sustainability is at the forefront of all our endeavors as we develop new products and build them to last longer.

We believe that footwear doesn't have to contribute to waste, rely on harmful chemicals, or deplete precious resources. Blumaka's clean foam offers brands a choice and extends an invitation to contribute to a positive impact, one shoe at a time.

Blumaka embodies my mother's directive to "Do Better," and we are thrilled to have you on the team.

Stuart Jenkins

Chief Innovation Officer

Blumaka